AP Racing Brake Kit (Rear 9541/380mm)- Porsche 991, 997

- $4,799.00 USD

$4,799.00 USD- $4,799.00 USD

- Unit price

- per

Complete rear AP Racing by Essex Road Brake Kit for various 2004+ Porsche 911s:

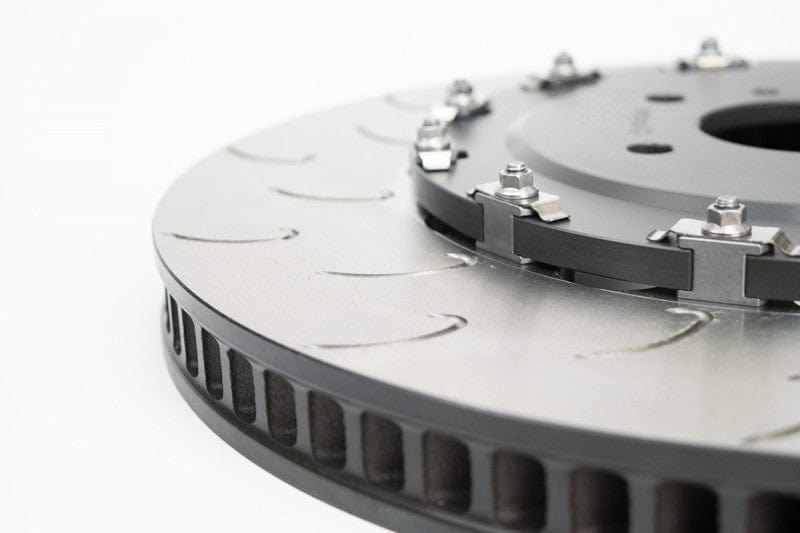

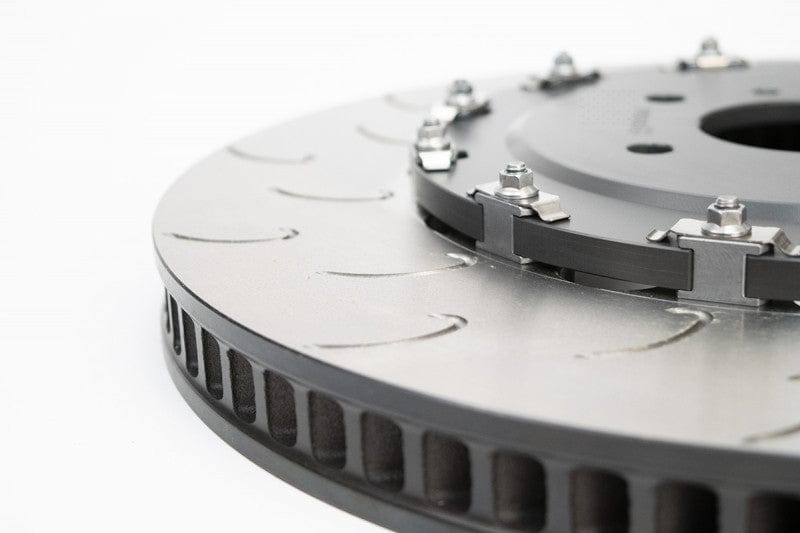

- Takes your brakes into GT3 territory with huge 380x28mm, 48 vane AP Racing J Hook discs

- Retains full function of OEM parking brake

- Painted calipers with dust boots add durability in inclement weather conditions

- Low noise, vibration, and harshness for a very OE-like experience during daily driving

- Leverages four piston AP Racing CP9541 World Radi-CAL II calipers with a red, black, or silver painted finish

- Pistons sized properly to maintain proper brake bias and work with the OEM master cylinder and ABS system

- Designed to mate with our front AP Racing Road Brake Kit

- Weighs roughly the same as an OEM rear 991 or 997 rear brake setup despite a huge size increase (330mm vs. 380mm)

WHAT'S IN THE BOX?

- One pair AP Racing CP9541 World Radi-CAL II four piston calipers

- One pair 380x28mm AP Racing CP5914, 48 vane, J Hook discs, with fully floating 6061 hard anodized aluminum hats, and attachment hardware

- One pair caliper mounting brackets and hardware

- One pair Spiegler Stainless Steel Brake Lines with abrasion resistant coating

- One set of Ferodo DS2500 Brake Pads

- Detailed installation instructions

CALIPERS

RADI-CAL

“Radi-CAL” is a blanket term used to describe AP Racing’s patented asymmetrical brake caliper design. Radi-Cal technology is grounded in Computer Aided Design (CAD) and Finite Element Analysis (FEA), and allows for organic, alien-looking designs that are a radical departure from conventional caliper designs of the past. Radi-CAL's are widely considered the pinnacle of current brake caliper technology. Since their inception in 2007, these revolutionary calipers have amassed a lengthy string of race victories at all levels of professional motorsport, while redefining brake performance expectations. For more details on the design concept and what these calipers have achieved in professional racing, please visit our blog and read The AP Racing Radi-CAL Story.

The key benefits of the Radi-CAL design:

- Massive Stiffness Increase- A 30+ % increase in both static and dynamic stiffness vs. conventional calipers allows for far less deflection under load, which means superior pedal feel & modulation, more even pad wear, and longer caliper service life.

- Considerable Mass Reduction- Removing all extraneous caliper mass lowers the caliper weight, despite the huge stiffness increases.

- Optimized Airflow- Air moves around and through the caliper more efficiently, providing superior heat evacuation and cooling.

- Efficient Packaging- The asymmetric caliper profile allows the caliper to fit into tighter spaces.

CP9541 WORLD RADI-CAL II (WRII)

It took eight years, numerous generations of the design concept, and advancements in manufacturing techniques, but the Radi-CAL finally evolved into a viable solution for enthusiasts of all levels and budgets. While many products are supposedly born in racing, there can be no doubt about the Radi-CAL pedigree. These calipers are direct descendants of the current crop of F1 and NASCAR Cup calipers. They don't look ordinary, because they're not ordinary. They're the epitome of racing design: elegant, sparse, and brutally effective. And while they embody and employ the Radi-CAL design philosophy of the past, they also add some outstanding new features that enhance their practicality, convenience, and appeal. Quite simply, they are the most technologically advanced brake calipers that have ever been within the common enthusiast's grasp.

Radi-CAL = Massive Dynamic Stiffness Increase

Over the years, many different strategies have been employed to shrink the brake caliper footprint while maintaining adequate stiffness: More robust caliper bridge designs, two-piece calipers with steel through-bolts, exotic materials (i.e. Beryllium, MMC), forging rather than casting, monobloc design, etc. All of these innovations pushed calipers towards becoming lighter, smaller, and stiffer. However, until the advent of the Radi-CAL, the same basic rectangular, boxy shape remained the accepted standard.

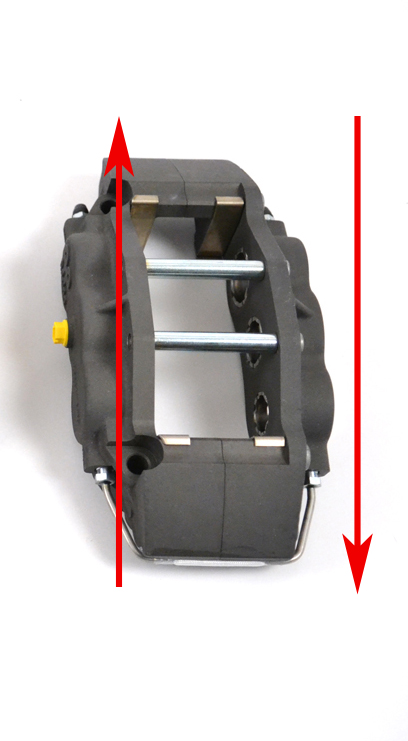

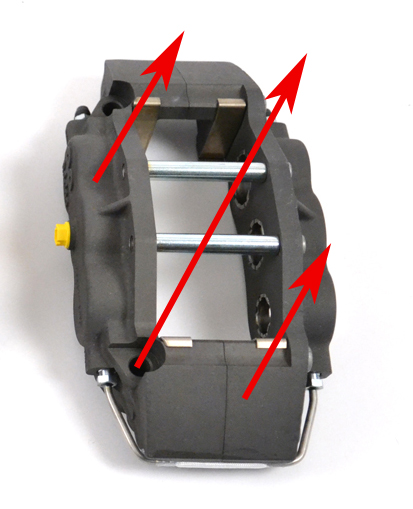

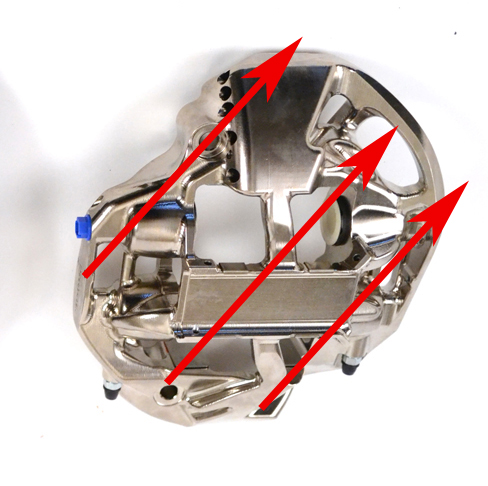

Is a rectangular box really the most appropriate and efficient shape for a brake caliper? AP Racing has now proven that it is not. As a brake caliper clamps brake pads against a spinning disc, a tremendous tangential friction force occurs between the pads and the spinning disc. In other words, the caliper is pulled strongly in the direction of the spinning disc, as represented by the downward pointing arrow on the right side in Figure 1 below. The caliper resists that force via the spindle hard mounting points, depicted by the upward arrow on the left. The dynamic load placed on the caliper twists or pulls the caliper into a parallelogram shape.

Figure 1

The dynamic force exerted on the calipers during a braking event is the key to the magic of the Radi-CAL design philosophy. Brake calipers of the past were designed to some extent in relative isolation from the forces that they were attempting to combat. They were designed to be the stiffest box possible while resting on a table, with much of the caliper mass residing at either end. The Radi-CAL is dramatically different because it was deliberately designed around the braking event forces that will be acting upon it. This is achieved by optimally distributing the body mass of the caliper on a diagonal, rather than at the two caliper ends. As such, the forces dynamically acting on the caliper are supported by the caliper mass, rather than what historically has been an empty box (see Figure 2 below). At the same time, this also allows for a significant reduction in overall mass, because all non-essential, non-load-bearing caliper body material is removed. So in the case of the Radi-CAL, it's not just about the material that is put into the caliper, it's about the material that is taken away!

Figure 2

WHAT DOES THE ABOVE MEAN FOR YOU, THE DRIVER? IT MEANS A SIGNIFICANTLY FIRMER BRAKE PEDAL WITH SUPERIOR MODULATION UNDER ALL CONDITIONS. IT ALSO MEANS MORE EVEN PAD WEAR WITH LESS TAPERING, AND A LONGER CALIPER SERVICE LIFE.

Radi-CAL= Lightweight, Compact Design with High Airflow

As mentioned above, the Radi-CAL design philosophy is just as much about what isn't there, as it is about what is there. The Radi-CAL design relocates caliper mass, creating voids that would traditionally not be located where they are. As such, considerable mass is removed from the caliper body, and the entire envelope of the caliper is optimized. The result is a lightweight and compact footprint, with pistons and brake fluid pathways that have far more surface area exposed to cooling air. The result is lower overall brake system operating temperatures and lower weight.

Many of our clients want to hop in their road car and drive to the track for the occasional HPDE on their OEM wheels and tires. The AP Racing World Radi-CAL II was designed with OEM wheel fitment in mind, and our brake packages won't have much trouble clearing many of today's 19" and 20" OEM wheels. Downloadable wheel fitment templates are available for every kit we offer, so be sure to check your specific wheels prior to ordering.

Two-piece, Forged Caliper Body

In racing, the Radi-CAL has traditionally been machined from a single, solid block of proprietary aluminum alloy (billet monobloc). With a billet monobloc design, the piston bores and piston seal grooves can only be machined with a right angle machine tool (the tool must be inserted up and into the caliper). As one can imagine, machining away all that material with special tools and multiple setups to achieve the final form is both time-consuming and costly. As a result, the price of a billet monobloc Radi-CAL has historically been prohibitive for anyone outside a professional race team. The World Radi-CAL II however, has been made possible by a newly developed forging process that allows conventional machine tools to access the piston bores via a direct path. The result is a drastic reduction in both production time and cost, while still retaining an incredibly stiff form. Forging also offers a more uniform grain structure than an equivalent cast part, providing greater strength and stiffness, which further contributes to superior pedal feel.

Elegant Red, Black, or Silver Painted Finish

The World Radi-CAL II is available in elegant red, black, or silver paint, offering hue options that won't clash with your vehicle's paint scheme. AP Racing conducts an extensive battery of durability testing on their painted finishes. The calipers are baked to extreme temperatures to simulate track use, sprayed with salt, and generally mistreated and abused before being approved for deployment. That means their beauty will not only surprise you when you pull them out of the box, but they will continue to look great for many years to come.

The overall finish quality of the World Radi-CAL II is unrivaled. Unlike some competing products that are assembled first then painted, The WRII is carefully masked and painted prior to assembly. They don't have over-spray on the dust boots, crossover tube, and bleed screws, and the result is a far more polished final appearance. Closeup photos also reveal the premium quality of AP's raw forgings, which lend themselves to an incredibly smooth final finish coat with relatively little orange peel.

AP Racing World Radi-CAL II finish

Competitor's painted caliper finish

Standard Anti-rattle Hardware

When you take your car out on date night, you don't want to hear rattling noises emanating from your brakes. All WRII calipers come with anti-rattle spring clips as standard. The spring clip places downward pressure on the top of the pad to dramatically reduce its movement both laterally and vertically. The result is a very OE-like experience, and no funny looks from your date when you pull up to the valet.

Piston Dust Boots for Dirt and Inclement Weather Protection

If you drive your car through four seasons, dust boots can come in handy. If you run calipers without dust boots, dirt and grime can accumulate on the sides of the caliper pistons. While that in itself is a problem, it can create a problem when it's time to change pads. In order to insert a fresh set of pads at full thickness, the pistons must be pushed back into the caliper. If the pistons are pushed back into the caliper with debris on them, the internal piston seals can be cut or deformed, resulting in a leak. One can either carefully wipe the pistons before retracting them into the caliper (as is the case with a competition or racing brake kit), or you can run dust boots on the pistons, which avoids the issue all together.

Below is what a dust boot looks like when the piston is extended. It keeps the walls of the piston covered/protected as the piston extends.

Simple Pad Change with Two Bolts

Changing pads is quick and easy with AP's World Radi-CAL II. AP’s bridge bolts pop out easily with a 6mm hex wrench. It will take you longer to pull off the wheel than it will to change pads. Less time futzing around and more time driving= fun!

Pistons Sized Specifically for Your Car

The piston sizes in our systems are specifically chosen to closely mimic the OEM brake torque on a given axle. As such, our front systems can be bolted to otherwise stock cars with no ill-effects, negative impact on ABS, etc. The vehicles stock master cylinder can remain, as can the OEM rear brake system.

High Volume Brake Pads

In a pure racing brake system, disc weight is a crucial consideration. A disc's radial depth (height of the disc's swept area) has a significant impact on how much it weighs. As such, racing discs typically have a radial depth no larger than 54mm. If you examine one of our Competition Brake Kits, or any of our professional racing systems, you'll find that none of the discs or corresponding pads have a radial depth taller than 54mm. You'll also find that those discs typically have an extremely high internal vane count and/or a special vane design such as AP Racing's Sinusoidal 'S' Vane pattern, designed to maximize airflow. These disc designs use the principle of convection to evacuate heat (if you envision the flow of air through the discs as a liquid). In racing, the overall disc mass can be reduced because the cars are consistently reaching speeds at which enough air is flowing through them to leverage these design features. The driver stands on the brakes for a few seconds, and then s/he is immediately hurtling towards the next turn while pushing a large volume of cooling air through the discs.

So what does that have to do with brake pads? A pad's volume is equal to its length x height x thickness. The greater the volume, the more mass it has to absorb heat. Without adequate mass, a brake pad quickly becomes heat-soaked, reaches its maximum operating temperature, potentially fades, and burns up very quickly. Since a race car may need to run up to 25 hours straight on a single set of brake pads, a considerable amount of pad mass is required. Unfortunately as described above, a racing disc's short radial depth substantially limits the pad height. That means greater pad volume must be achieved via increased pad length or thickness. If the pad is too long, the backing plate could warp, the pad material could fracture, and pad taper might become problematic. That's why eight piston calipers with a single pad per side never seem to work very well. The only remaining option to increase pad volume is via increased thickness, and in pro racing we use pads up to 30mm thick. The problem with using extremely thick pads however, is that they require a very wide caliper to accept them! If you look at a Competition Radi-CAL vs. a Road Radi-CAL, you'll note that the Competition Radi-CAL will almost always be wider. While wide calipers fit well on a race car designed to accommodate them, they don't always integrate smoothly on a road car. That means a different methodology must be employed to keep brake temperatures and wear rates under control on road cars, which won't be traveling at 100mph+ most of the time (unless the owner wants to be arrested!).

The solution to gain a large amount of pad volume while taking packaging requirements into account is a four piston caliper with a pad that is both longer and has a fairly tall radial depth. The heat is spread over a larger surface area, relying on the principle of radiation to remove heat into the air surrounding the disc. With the CP9541 World Radi-CAL II, our rear pad has more volume than the front pads in many of our competitors' calipers, as well as many OEM front calipers!

So what does the above mean for you? It means that even though our road brake system is designed around narrower Radi-CAL calipers than we usually employ in racing, the large pad volume will help ensure that it's still going to be incredibly capable and durable when pushed to the limit. The large pads mated to our chosen discs will shrug-off a massive wallop of deceleration and its resulting heat. Our Road Kits are fully capable of handling the occasional track day without being stressed. It also means that the pads and discs are going to last a very long time under light load conditions, like when you're cruising to Cars and Coffee or running the canyons.

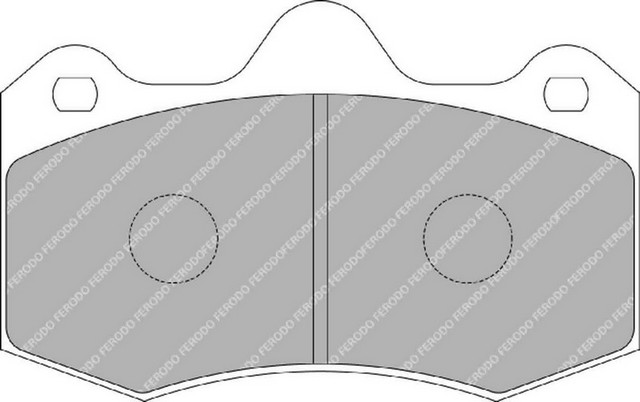

Below is a drawing of the pad shape used in the CP9541.

Dimensions= 130.3mm x 81mm x 16.9mm, D55

Ferodo Racing DS2500 Brake Pads Included

You only get one chance to make a first impression, which is why we include a set of Ferodo DS2500 pads in every AP Racing by Essex Road Brake Kit. Although we always recommend using a dedicated race pad for the track, the Ferodo DS2500 is one of the best hybrid street/track pads on the market. It features the moderately high bite and solid fade resistance of a track pad, with the low noise levels and non-corrosive dust of a street pad. During aggressive driving the DS2500 is known for its flat torque curve, which means as temperatures go up, the response through the brake pedal remains consistent. If you drive aggressively on the street, do some canyon runs, autoX, and maybe some light track duty on street tires, the DS2500's broad range of capability is impossible to beat. Please visit our Ferodo Racing brake pad page for more details on these fantastic pads.

Spare Ferodo DS2500 pads for the CP9541 World Radi-CAL II caliper can be found here

If you're looking to push your car extremely hard on the track, we'd suggest the Ferodo Racing DS1.11 Compound. The DS1.11 is one of Ferodo Racing's latest endurance race pad offerings. The DS1.11 is known for its extremely flat torque curve, which means that as temperatures go up, the response through the brake pedal remains consistent. The DS1.11 can be thrashed all day without having it burn up or fade, it's easy on discs, and doesn't have many of the judder or vibration issues that competing products have. If you want an extremely solid, all around race pad that will perform well and last a long time, the DS1.11 is the perfect choice.

Kies Recommended Products

Recently Viewed Products

- Choosing a selection results in a full page refresh.